O-rings are used in just about every industry and typically to block the flow of liquids, gasses, or other materials. Their actual makeup and function are a bit unique, however. Why? In order to function properly the O-ring must deform.

Basically, O-rings are doughnut-shaped parts that are installed in cavities known as glands and compressed into the cavity to form a seal. To ensure proper functionality the O-ring’s material, design, selection for the application, and installation must all be carefully controlled. If not, the O-ring (and potentially the entire piece of equipment it is installed in) could fail.

The most common causes of O-ring failure are:

- Incorrect size O-ring selected for the application

- Material and environmental incompatibility

- Improper design

- Improper installation

- And more

If an O-ring fails, the cause of that failure can be complex and difficult to evaluate. The most common types of O-ring failure that can occur include (but are not limited to):

- Abrasion

- Compression Set

- Damage During Installation

- Excessive Swelling

- Explosive Decompression

- Extrusion or Nibbling

- Heat Hardening or Oxidation

- Spiral Failure

- Weather or Ozone Cracking

- And more

| Failure Reason | What causes it | How to identify it |

| Abrasion | Poor lubrication, excessive temperatures, fluid contaminated with abrasive particles, and more. | A flattened surface on the O-ring indicates abrasion damage. |

| Compression Set | Excessive swelling, low heat resistance, squeezed too hard to achieve a seal, incomplete curing during manufacture, and more. | Flat surfaces on both sides of the O-ring’s cross section. |

| Damage During Installation | Sharp edges on mating components, sharp threads, oversized O-rings, O-ring twisted or pinched, improper lubrication, and more. | Short cuts or notches on the O-ring or skinning/peeling surface. |

| Excessive Swelling | The O-ring absorbed surrounding fluids and swelled due to incompatible material and environment. | A dramatic increase in the O-ring’s dimensions. |

| Explosive Decompression | Absorption of gasses at high pressures, or rapid decreases in pressure that causes the O-ring’s micropores to trap gasses. | Random short splits or ruptures deep in the O-ring’s cross section. Can also appear on the surface as small blisters. |

| Extrusion or Nibbling | Excessive system pressure, O-ring made of material that is too soft for the application, fluid degradation of the O-ring, irregular gaps, improper O-ring size, and more. | Small pieces or “nibbled bites” taken out of the O-ring. |

| Heat Hardening or Oxidation | Excessive temperatures applied to incorrect O-ring material for that application can cause hardening, evaporation of plasticizers, and cracking. | The O-ring surface appears pitted or cracked, often with flattened areas. |

| Spiral Failure | This is caused by simultaneous sliding and rolling of different segments of the O-ring. | The surface of the O-ring exhibits a series of deep, spiral, 45° angle cuts. |

| Weather or Ozone Cracking | O-rings made with improper materials that are exposed to ozone or other atmospheric pollutants. | Appears as small surface cracks perpendicular to the direction of the stress. |

Finding the right seal

Choosing the right O-ring is critical to ensure a proper seal. However, finding the right seal for your application can be challenging. Prior to selecting a seal, it is best that you consult an expert. While the right materials or finishing treatment for your application is best defined by your process engineer, we are always here to assist you.

How can we help you?

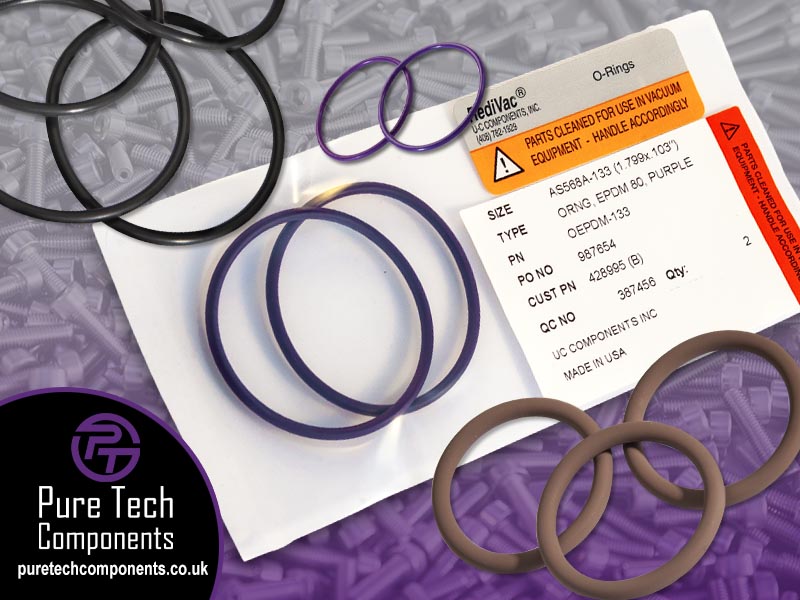

Pure Tech Components is the premier UK distributor for UC Components, Inc. RediVac® line of fasteners, washers, hex nuts, and O-rings. We provide only the best specialised fasteners to a wide range of industries, including medical, food processing, optical, vacuum, semiconductor, and R&D. Partnering with us gives you the confidence and reassurance you need to concentrate on your customer’s needs without worrying or compromising on cost, quality, or customer service. Contact us today for more information or to place an order.