We are the premier UK distributor for UC Components, Inc. RediVac® line of fasteners, washers, hex nuts, and O-rings.

Component Finishing

We offer a range of finishes for the entire RediVac® line of fasteners, washers, and nuts. These coatings and platings are designed to prevent galling and/or improve the corrosion resistance of the treated component. All coatings and platings listed here are vacuum compatible, dependent on your specific process chemistry. The right coating or plating for your specific HV or UHV application is best defined by your process engineer.

We offer the following finishing processes:

Precision Cleaned

(no suffix/-N)

This proprietary precision cleaning process significantly reduces or eliminates surface particulates and other organic surface contaminants, utilising a variety of cleaning methods and state-of-the-art vacuum packaging equipment. All precision cleaning and packaging is performed within a certified, Class 100/ISO Class 5 Cleanroom.

Silver Plated

(-A/-NA)

Vacuum-stable silver plating is available for all RediVac® fastener components. These silver-plated screws, hex nuts, and washers exhibit excellent anti-galling properties, high lubricity, a wide operating temperature range, good corrosion resistance, and exceptional conductivity.

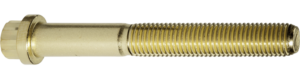

Gold Plated

(-AU/-NAU)

Stable in vacuum, gold plating is available for all RediVac® products. These gold plated screws, hex nuts, and washers provide an outstanding combination of screw galling prevention properties, a wide operating temperature range, exceptional conductivity, good corrosion resistance, high lubricity, and cosmetic appeal.

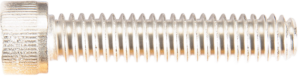

Nickel Plated

(-K/-NK)

We offer electroless nickel plating for all RediVac® products. These nickel plated screws, washers, and hex nuts provide effective corrosion resistance as well as good wear resistance and galling prevention in high vacuum systems and other environments. For components in extremely corrosive environments, such as fluorine gas, please inquire about RediVac® Nickel 200 fasteners, including screws and washers.

MoS2 Coated

(-C/-NC)

All RediVac® screws, washers, and hex nuts are available with MoS2 (molybdenum disulfide) coating. MoS2 coating provides vacuum compatible lubrication and improves component wear resistance. This MoS2 coating is applied without chemical binders and is impinged into the product’s surface; ensuring dimensional integrity while minimising flaking, chipping, and peeling.

WS2 Coated

(-W/-NW)

We offer WS2 coating for all RediVac® screws, washers, and hex nuts. WS2 (tungsten disulfide) coating provides vacuum compatible lubrication and improved wear resistance for treated components. This WS2 coating is applied without chemical binders and is impinged into the product’s surface to ensure dimensional integrity and minimise screw galling, flaking, chipping, and peeling.

Electropolished

(-EP/-NEP)

Electropolished finish is available for all RediVac® screws, washers, and hex nuts. The electropolishing process carefully dissolves unwanted surface metals. It leaves behind the true base metal(s) of a component and significantly reduces surface burrs, chips, and peeling; which is especially important for threaded components. Electropolishing also greatly reduces surface particulate, improves corrosion resistance, helps reduce outgassing, and imparts a bright, chrome-like finish.

Kolsterising®

(-KOL/-N-KOL)

Kolsterising® is an industry-proven, thermo-chemical, low-temperature, diffusion-based, surface hardening technology used to enhance certain grades of stainless steel, cobalt, and nickel-based alloys. Kolsterising® is not a coating but a low-temperature surface carbon diffusion treatment that enhances the hardness of the base material. The process adds large concentrations of carbon atoms that form high compressive stresses on the surface. These stresses and the filling of the interstitial sites by the carbon atoms not only significantly improves the hardness of the material, but also makes the surface resistant to corrosion, wear, and fatigue.

Vacuum Baked

(-BV)

The RediVac® Vacuum Baking Process offers an added level of cleanliness assurance by minimising residual hydrocarbons and water vapor, to greatly reduce outgassing and residual surface contaminants. By baking-out under vacuum, these products can meet or exceed the requirements of many of today’s leading scientific research facilities, beam lines, and test chambers operating HV, UHV, and EUV environments.

Every RediVac® fastener, washer, hex nut, and O-ring goes through the proprietary UC Components, Inc. multi-stage precision cleaning and packaging processes prior to shipment, ensuring that the components you receive are ready for immediate installation into your HV, UHV, or EUV system. By reducing additional vacuum preparation steps, RediVac® components help you run faster and leaner.

Finishes, Lubrication & Torque Values

Torque value is primarily dependent on friction produced by both the threads and the material in contact with the fastener head. The addition of lubrication, coating, or plating will reduce the coefficient of friction resulting in a higher tension or clamping force for a given torque. Caution must be exercised as the tensile strength of a fastener can be exceeded without exceeding its maximum recommended torque.