Parts and fasteners for high and ultra-high vacuum applications are required to be free from volatile materials that would lead to contamination of the entire vacuum system. However, can you use an untreated O-ring in a vacuum system even though tests have shown that untreated O-rings will outgas under vacuum?

Quick Overview of Outgassing

Outgassing (or offgassing) refers to releasing gas that is trapped, frozen, dissolved, or absorbed in some other material. Outgassing is a common problem when creating and maintaining a clean high-vacuum environment. High-vacuum and high-temperature environments increase the rate of outgassing due to vapor pressure and an increase in chemical reactions in the polymers. With proper preparation and the right parts, you can drastically reduce the amount of outgassing in your vacuum system.

Figure 1 : O-Ring Bake-Out Residue

Virgin/Untreated O-Rings

There are a variety of O-rings on the market today which vary widely from manufacturer to manufacturer, the source of the materials used, and even from lot to lot. A new O-ring can potentially contain trace amounts of contaminants such as solvents, water / water vapor, volatile curing agents, unreacted monomers, and more.

New, untreated, O-rings require long-term room temperature pumping periods to remove water contaminates from the polymer. Contaminates slowly diffuse to the surface and then desorb which can take weeks (and even months) to properly condition. Treating the O-rings by baking out the water vapor prior to installation will drastically reduce the possibility of outgassing.

Baked vs Non-Baked

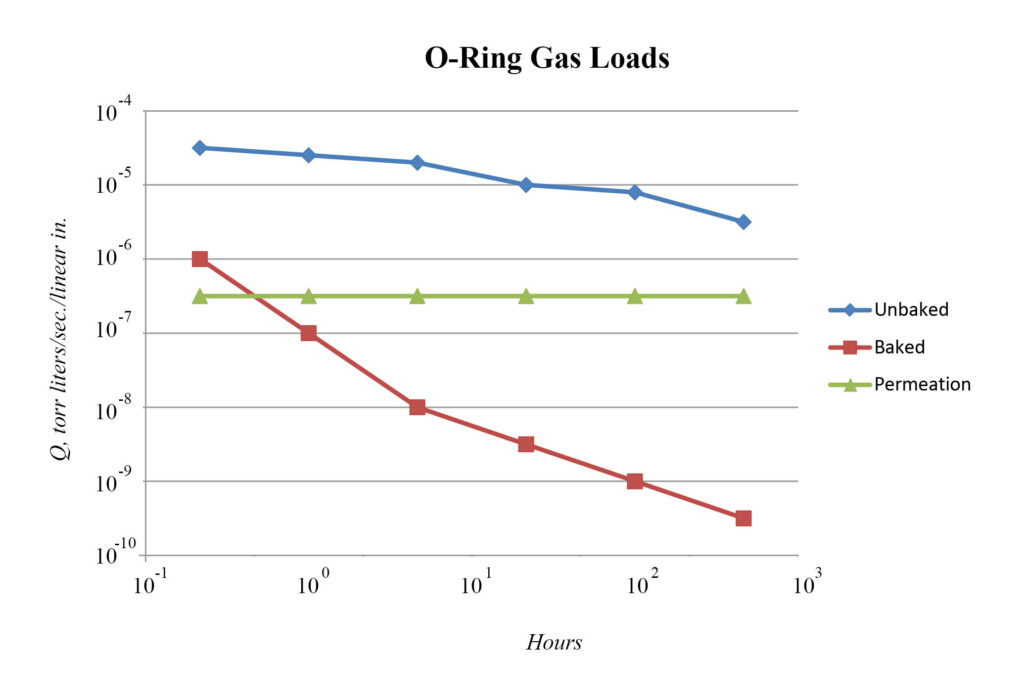

As you can see in the table (figure 2) below, the outgassing rate decreases dramatically with pump time utilizing baked O-rings versus non-baked O-rings. The rate shown here is representative of the common variations, though practical outgassing will fall somewhere between the two curves.

Figure 2 : O-Ring Gas Loads

Using untreated O-rings in vacuum applications has been proven to outgas; one of the best, and easiest, ways to help reduce outgassing is the use of specifically formulated and treated O-rings in HV, UHV, and EUV environments.

How can we help you?

We Offer Top Quality Solutions

RediVac® O-rings are specially processed for immediate use in High Vacuum and Ultra High Vacuum equipment. All fasteners and O-rings are cleaned and packaged in a certified Class 100/ISO Class 5 Cleanroom. This process is based on typical requirements for pre-cleaning elastomer seals prior to installation for vacuum service. The Vacuum Baking Process is also just one of the finish options that we offer for the family of RediVac® precision cleaned and clean-packaged fasteners, washers, hex nuts, and O-ring products.

Pure Tech Components is the premier UK distributor for UC Components, Inc. RediVac® line of fasteners, washers, hex nuts, and O-rings. We provide only the best specialised fasteners to a wide range of industries, including medical, food processing, optical, vacuum, semiconductor, and R&D. Partnering with us gives you the confidence and reassurance you need to concentrate on your customer’s needs without worrying or compromising on cost, quality, or customer service. Contact us today for more information or to place an order.