A virtual leak is a trapped volume of gas within a vacuum chamber that cannot be easily pumped out due to restrictions in the path connecting the trapped gas to the main chamber. Virtual leaks reference a leak that cannot be found during any activities or tests performed outside of the vacuum chamber. The presence of a virtual leak will become apparent during the system pump-down cycle if the system cannot keep up with the gas load from the leak. The correct system pressure will either not be able to be reached or will take an excessive amount of time to reach.

For example, if the chamber has an internal weld crack that is too small to see and you begin the pump-down process and the pressure in the chamber drops, the gas from the crack will cause a small but continuous gas load flowing into the chamber.

Fasteners are typically the source of virtual leaks in sealed systems. The specific areas that are involved are described in the table below:

| Voids | ||

| Symbol | Name | Description |

| FT | Filled Threads | Voids in the screw threaded portion |

| CV | Clear Volume | Clear hole between parts |

| EV | End Volume | Volume between screw & hole end |

| Solutions | ||

| Vented Screw | Helps clear all volumes | |

| Vented Washer | Speeds pumping of CV | |

| Vented Hole | Speeds pumping of EV | |

Any fastener that is used inside of a vacuum system can result in voids between the parts being restrained, the threads and shoulder of the screws, and incompletely filled holes. Often these voids are partially sealed by the fastener, but if sealed the seals will break in time.

How can this problem be solved?

Virtual leak problems can be eliminated with the use of vented fasteners. Vented Screws (also known as Vacuum Screws, Ventilation Screws, or Hollow Screws) feature a hollow core (has a hole drilled through it) and are specially designed to allow the release of gases, contaminants, and pressure through the fastener.

Vented screws, washers, and nuts are specifically designed to combat issues with blind-tapped holes in vacuum systems. Blind-tapped holes, by definition, leave a small void beneath the applied fastener. This void, created during assembly at atmosphere, results in air, particulate, and other potential forms of contaminants to be left in place. During the pump-down process this volume of air will become significant as the relative pressure in the chamber drops. Over time, this trapped volume of air will eventually work its way up around the threads causing a virtual leak.

How do vented fasteners solve this problem?

We offer a wide range of RediVac® vented screws, nuts, and washers specifically to combat problems like virtual leaks. These products provide a path for trapped air to be pumped away from the bottoms, sides, and shoulders of blind-tapped holes. This allows for faster, more thorough pump-down of your vacuum systems and eliminates virtual leaks as well as potential contaminants that can be found in these voids. RediVac® vented screws promote higher system throughput and improved yield.

Is installing a vented screw different from a standard screw?

Installing a vented screw is a simple process requiring no special tools or tricks—it installs just like a standard, non-vented screw and is most effective when used in conjunction with one of our vented flat washers.

Check out this quick overview video for more on vented screws:

How can we help you?

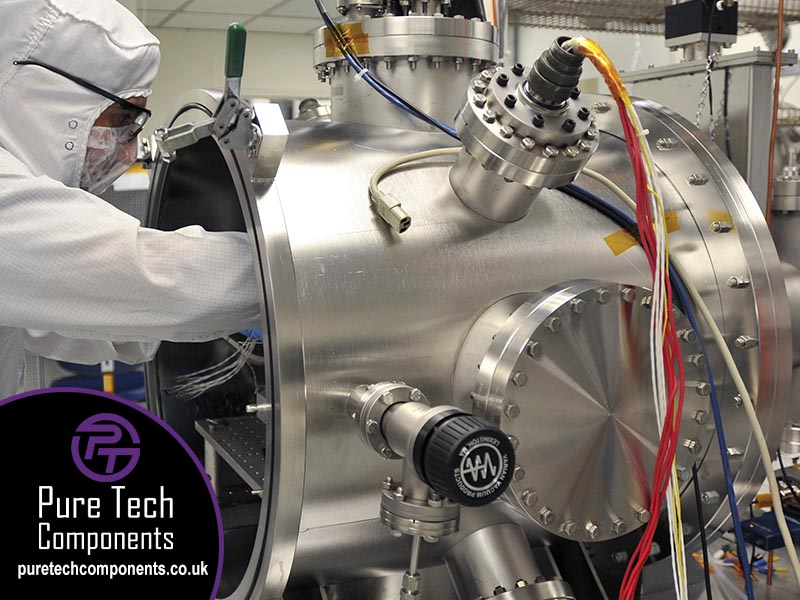

Pure Tech Components is the premier UK distributor for UC Components, Inc. RediVac® line of fasteners, washers, hex nuts, and O-rings. We provide only the best specialised fasteners to a wide range of industries, including medical, food processing, optical, vacuum, semiconductor, and R&D. Partnering with us gives you the confidence and reassurance you need to concentrate on your customer’s needs without worrying or compromising on cost, quality, or customer service. Contact us today for more information or to place an order.