What is outgassing and how does it affect your system?

Outgassing, also called offgassing, refers to the release of gas that has become trapped, frozen, dissolved, or absorbed in another material. If left in a high-vacuum system, the gas will eventually condense on sensitive equipment and other surfaces, which could potentially render the system inoperable. Outgassing is a common problem when creating, or maintaining, a clean high-vacuum environment.

What are the most common sources of outgassing?

Many different materials release lightweight molecules that can interfere with the vacuum process, even materials that are not normally considered absorbent (such as metals and glass). Vapor pressure and the rate of chemical reactions at higher temperatures also cause outgassing rates to increase.

The worst sources of outgassing are:

- Plastics

- Elastomers

- Glues

- Porous ceramics

- Porous metals

- Most lubricants

- Heat transfer greases

- Fingerprints, hair, & skin cells

- Dust

- Food

- and more

The most common outgassing issues come from:

- Water vapor

- Oil

- Grease vapor

- Solvents

- Organic materials

Outgassing rates of common materials:

| Material | Rate* (10-9 mbar/sec-cm2) | Rate** (10-8 Torr-liter/sec) |

| Stainless Steel | 13.5 | — |

| Chrome Plated Steel | 7.1 | — |

| Electropolished Stainless Steel | 4.3 | — |

| Aluminum | 6.3 | — |

| Nitrile | 3,500 | 300 |

| KEL-F | 40 | 4 |

| Silicone | 18,000 | 2,000 |

| Fluoroelastomer | 1,140 | 2,000 |

| Baked Fluoroelastomer | 4 | 0.2 |

| Perfluoroelastomer | — | 0.3 |

| PTFE | 300 | 400 |

| Polyimide | 900 | 80 |

| Pyrex Glass | 7.4 | — |

*Leybold Inficon, Inc., “Vacuum,” 1997

**Peacock, R.N., J. Vac. Sci. Technol., Jan./Feb. 1980

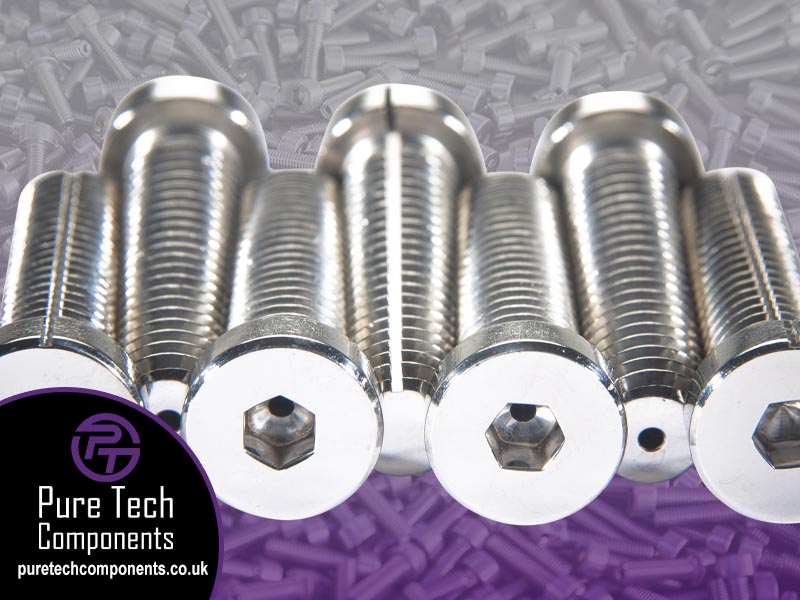

Common fasteners, such as bolts and screws, are needed in virtually every machine and their effectiveness is a key consideration when assembling any type of machinery. Therefore the materials used in their creation and post-fabrication treatments are vital to manufacturers, particularly if they will be used where they will be exposed to corrosive elements, extreme temperatures, extreme pressure, or high levels of physical strain.

With proper manufacture and preparation of your fasteners you can drastically reduce the amount of outgassing in your vacuum system. Utilizing the proper fastener, cleaning surfaces properly, and/or heating individual components (a process called “bake-out”) can help virtually eliminate outgassing in your system.

How can we help you?

Pure Tech Components is the premier UK distributor for UC Components, Inc. RediVac® line of fasteners, washers, hex nuts, and O-rings. We provide only the best specialised fasteners to a wide range of industries, including medical, food processing, optical, vacuum, semiconductor, and R&D. Partnering with us gives you the confidence and reassurance you need to concentrate on your customer’s needs without worrying or compromising on cost, quality, or customer service. Contact us today for more information or to place an order.